For robots to be useful for real-world applications, they must be safe around humans, be adaptable to their environment, and operate in an untethered manner. Soft robots could potentially meet these requirements; however, existing soft robotic architectures are limited by their ability to scale to human sizes and operate at these scales without a tether to transmit power or pressurized air from an external source. In this project, we have developed an untethered, inflated robotic truss, composed of thin-walled inflatable tubes, capable of shape change by continuously relocating its joints, while its total edge length remains constant. A set of identical roller modules each pinch the tube to create an effective joint that separates two edges, and modules can be connected to form complex structures. Driving a roller module along a tube changes the overall shape, lengthening one edge and shortening another, while the total edge length and hence fluid volume remain constant. This isoperimetric behavior allows the robot to operate without compressing air or requiring a tether. Our concept brings together advantages from three distinct types of robots—soft, collective, and truss-based—while overcoming certain limitations of each. Our robots are robust and safe, like soft robots, but not limited by a tether; are modular, like collective robots, but not limited by complex subunits; and are shape-changing, like truss robots, but not limited by rigid linear actuators. With the same collective of robots we can construct a variety of truss structures including two-dimensional (2D) robots capable of shape change and a human-scale 3D robot capable of punctuated rolling locomotion and manipulation.

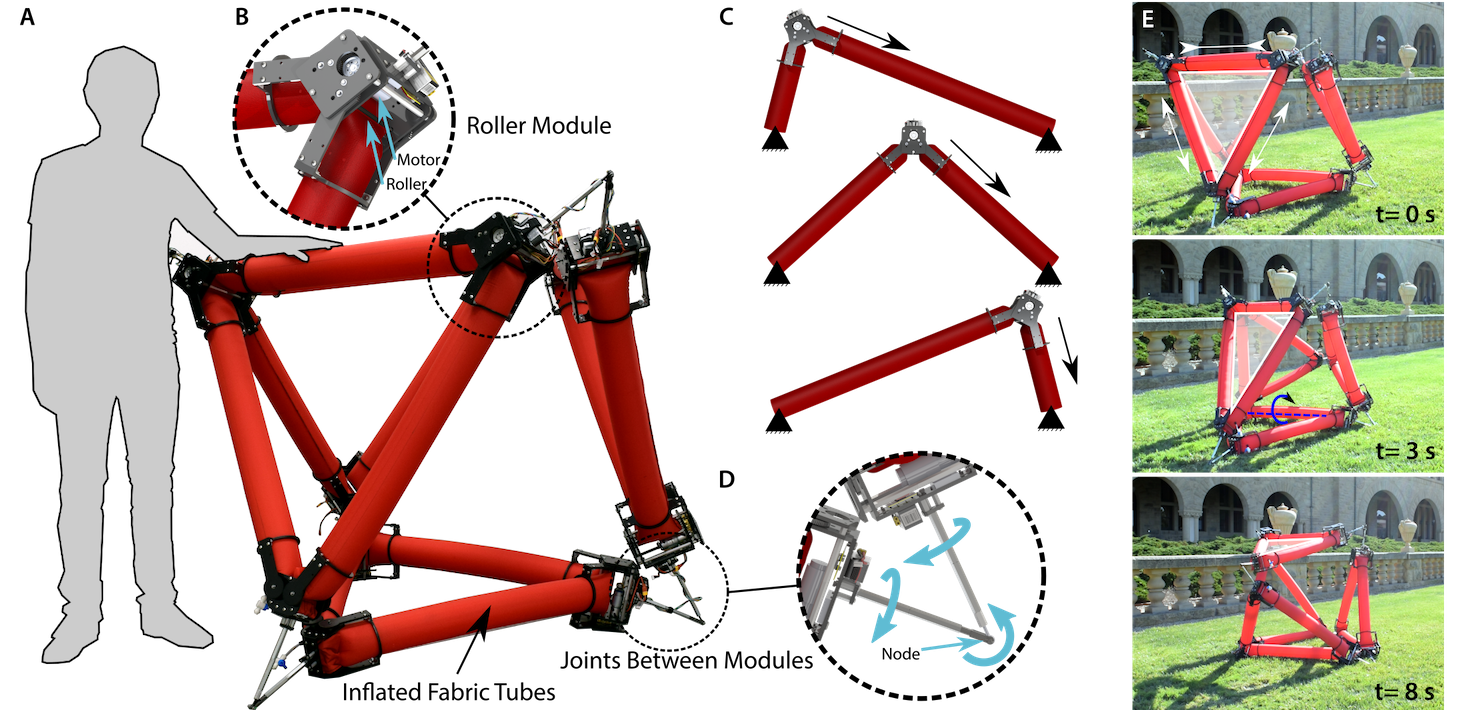

An overview of the components and operating principle of the robot. (A) A large-scale inflated robot that does not require a tether. The robot is composed of a set of identical robotic roller modules that are mounted onto inflated fabric tubes that form the primary structure of the robot. (B) The rollers pinch the fabric tube between rollers, creating an effective joint that can be relocated by driving the rollers. (C) The roller modules actuate the robot by driving along the tube, simultaneously lengthening one edge while shortening another. The roller modules can connect to one another to construct 2D and 3D truss-like structures capable of shape change and locomotion. (D) The roller modules connect to each other at nodes using three-degree-of-freedom universal joints that are composed of a clevis joint that couples two rods, each free to spin about its axis. The arrows indicate how the joints can rotate. (E) The robot locomotes untethered outdoors using a punctuated rolling gait. One face of the robot is highlighted to illustrate the rolling motion.

Papers

*,+ These authors contributed equally.

Selected Press

- Stanford engineers create shape-changing, free-roaming soft robot (March 18, 2020). Stanford News.

- Soft Robot, Unplugged (March 18, 2020). The Current.

- Stanford Makes Giant Soft Robot From Inflatable Tubes (March 18, 2020). IEEE Spectrum.

- Watch robot change its shape like a ‘Transformer’ (March 20, 2020). CNN.

- This shape-shifting soft robot can perform multiple functions (April 1, 2020). Medium.

- Stanford’s shape-shifting ‘balloon animal’ robot could one day explore space (March 25, 2020). Digital Trends.

- A “Human-Scale Soft Robot” Could Make Deliveries in a Quarantine (March 19, 2020). Inverse.

- Baymax on Mars? Shapeshifting ‘Soft’ Robot Could [Literally] Transform Planet Exploration (March 18, 2020). Syfy.

- New robot developed at Stanford changes shape like a ‘Transformer’ (March 21, 2020). TechRepublic.

- Shape-changing inflatable robot can nab objects and roam on its own (March 18, 2020). New Atlas.

- Researchers Create Soft Robot Able to Change Shape and Roam (March 19, 2020). Unite AI.

- Stanford engineers create a new robot that combines traditional and soft robotics (March 19, 2020). SlashGear.

- Stanford Engineers Create Inflatable, Shape-Shifting Soft Robot (March 23, 2020). Core 77.

- Leinen los für aufblasbare Roboter (March 18, 2020). heise.

- 科学家研发可变形充气机器人 可以抓取物体并自行漫游 (March 19, 2020). cnBeta.

- Realizzato un soft robot che cambia sembianze a seconda delle esigenze (March 19, 2020). RSVN.

- Инженеры создали мягкого робота, способного менять форму во время движения (March 19, 2020) Хайтек.

- And more

1 Department of Mechanical Engineering, Stanford University, Stanford, CA, USA.

2 Department of Aeronautics and Astronautics, Stanford University, Stanford, CA, USA.

3 Department of Mechanical Engineering, University of California, Santa Barbara, Santa Barbara, CA, USA.

Funding: S.F., A.M.O., E.W.H., and Z.M.H. acknowledge support from the NSF under grant no. 1637446. M.S. and N.S.U. acknowledge support from DARPA YFA under grant no. D18AP00064. M.S., S.F., E.W.H., Z.M.H., and N.S.U. acknowledge support from the NSF under grant no. 1925030. E.W.H. acknowledges support under NSF grant no. 1925373.