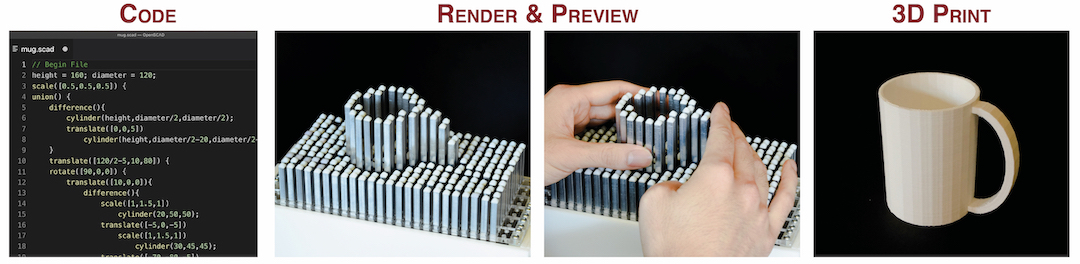

We investigate an accessible 3D modelling workflow (shapeCAD) where 3D models are generated through OpenSCAD, a declarative programming language for 3D modeling, and rendered at interactive speeds in a 2.5D shape display consisting of a grid of 12×24 actuated pins.

Affordable rapid 3D printing technologies have become key enablers of the Maker Movement by giving individuals the ability to create physical finished products. However, existing computer-aided design (CAD) tools that allow authoring and editing of 3D models are mostly visually reliant and limit access to people with blindness and visual impairment (BVI).

Through a series of co-design sessions with three blind users of mixed programming ability, we identify accessibility challenges in existing 3D modelling scripting tools and design interactions to support dynamic feedback of scripts using a 2.5D tactile shape display. With these insights, we implement shapeCAD. Interacting with shapeCAD, BVI users are able to leverage the low resolution output from a 2.5D shape display to complement programming of 3D models. shapeCAD allows users to haptically explore and modify existing models, and to author new models. We further validate usability and user experience through an evaluation with five BVI programmers. In a short period of time, novices were able to design a range of new objects. BVI users can bring a valuable perspective to design and it is imperative to increase accessibility in tools that enable this community to also participate as designers.

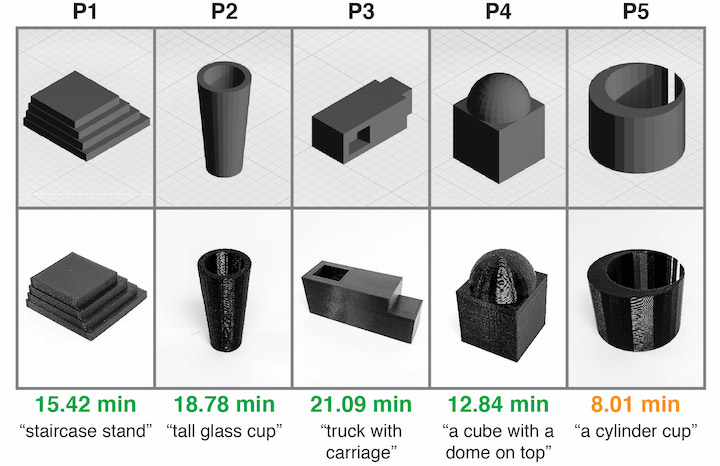

Objects created by all participants during the evaluation’s free form task, the time it took to create them, and participant’s description of the object. The first row shows the rendering of the 3D model and the second row shows the object 3D printed using a MakerBot Replicator. All participants reported being satisfied with the final results except P5.

Papers

Work-in-Progress

Selected Press

- Stanford increasing access to 3D modeling through touch-based display (October 29, 2019). Stanford News.

- This tactile display lets visually impaired users feel on-screen 3D shapes (October 31, 2019). TechCrunch.

- Stanford increasing access to 3D modeling through touch-based display (October 29, 2019). Eureka News.

- Stanford increasing access to 3D modeling through touch-based display (October 29, 2019). Science Daily.

- Researchers increasing access to 3-D modeling through touch-based display (October 29, 2019). TechXplore.

- Touch-Based Display Boosts 3D Modelling Accessibility (October 30, 2019). Futurity.

- Stanford University Unveils Pin Art-Like Tactile 3D Display for Visually Impaired 3D Modelers (October 30, 2019). Hackster.

- Stanford Increasing Access to 3D Modeling Through Touch-Based Display (November 1, 2019). Environmental News Network.

- 4 Awesome Discoveries You Probably Didn’t Hear About (November 8, 2019). National Science Foundation.

- Stanford Researchers Develop Tactile Display to Make 3D Modeling More Accessible for Visually Impaired Users (December 3, 2019). Core 77.